PRODUCT

Material: Stainless steel 304

Finish: Plain

Standard: ISO14581

Certification: ISO9001

MOQ:1000PCS

Samples: Free

Place of Origin: Zhejiang China

Product Details

Stainless steel Torx Countersunk head Self Tapping Screws Wood Screw

A flush-set, corrosion-proof joint in hardwood, softwood, plywood or MDF is achieved with one high-torque turn. These screws combine A2 (304) or A4 (316) stainless steel with a sharp Type-C wood thread, a 90° countersunk head and a deep Torx drive—ideal for visible joinery, kitchen worktops, decking fascias and marine carpentry.

| Product Name |

self tapping screw |

| Material | Alloy Steel,Carbon Steel,Stainless Steel |

| Grade | 4.8,8.8,10.9,12.9,A2,A4 |

| Finish |

Plain,Passivated,Dacromet Black,Dacromet Gray,Nickel Plated,Color Zinc Plated,Black Oxide,Hot-Dipped Galvanizing,etc. |

| Head Type |

Binding Head,Hex Head,Pan Head,Hex Washer Head,Socket Head,Truss Head,Flat Head,Oval Head,Round Head, Pan Washer Head,etc. |

| Drive Type |

Phillips,Slotted,Phillips-Slotted Combo,Pozi, Socket,Torx,Torx-Slotted Combo,Torx Pin,etc. |

| Size | Metric,Inch |

| Customized | Available |

| Sample | Free in stock (The express should be paid by buyer) |

| 304 Chemical Composition(%) | ||||||||

| Grade | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | N≤ |

| 0.08 | 2 | 0.75 | 0.03 | 0.045 | 18.0-20.0 | 8.0-10.5 | 0.1 | |

| 304 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | Hardness(HB)(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200 |

Standard export packing or According to customer's requirement

Q:What is your main products?

A:Fasteners, Bolt, nut, screws, washer, threaded rod, anchors, self tapping screws, self driling screws, stainless steel plate, etc.

Q: What is your delivery time?

A:It depends on if we have stock or not, if we have stock goods, we can delivery within 2 days after receive the payment. And normally our production is in 20-30 days for one container (20-26 ton) products.

-

Material: A2-70 (304) ≥ 700 MPa tensile; optional A4-80 (316) ≥ 800 MPa for coastal or chemical environments

-

Head: Countersunk 90° (DIN 7991 form) – sits flush or slightly below surface; decorative or hidden fixings

-

Drive: Torx T10–T30 – 6-lobe contact gives 40% more torque than Phillips, zero cam-out, perfect for impact drivers

-

Thread: Type-C (wood) with 45° gimlet point – wide, deep thread for maximum pull-out resistance; optional hi-low or twin-lead

-

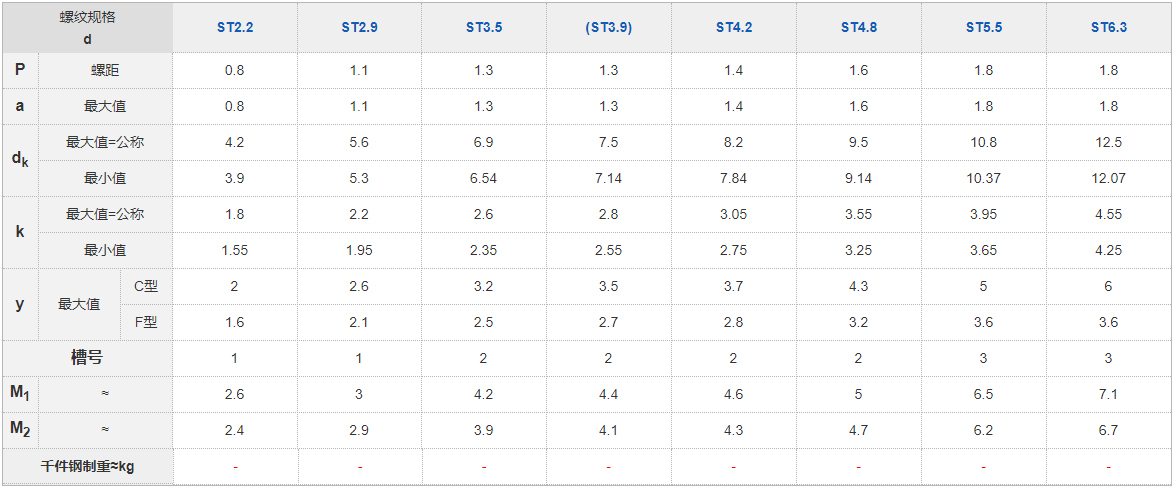

Dia. & Length: #6 (3.5 mm) – #12 (5.5 mm) × 20 mm – 120 mm (3/4" – 4 3/4")

-

Finish: Bright polished & passivated; optional black-ceramic or sand-blast top-coat

-

Salt-Spray: > 1,000 h (ASTM B117) on A2; > 1,500 h on A4

-

Temp. Range: –40 °C to +300 °C with full corrosion resistance

✔ Invisible Finish – head disappears below timber surface; plug or filler covers the drive recess for hidden joints

✔ High Pull-Out Strength – deep Type-C thread grips hardwood and engineered boards without stripping fibres

✔ Marine-Grade Rust Protection – no bleeding or staining on teak, iroko or composite decking

✔ Tool Efficiency – Torx drive transmits full driver power; reduces cam-out and bit wear

-

Pilot Hole: 2 mm for hardwood > 40 mm; no pilot needed in softwood

-

Countersink: 90° cutter or pre-machined pocket for flush finish

-

Drive Speed: 1,000–2,000 rpm – use Torx bit of matching size; stop when head seats flush

-

Isolation: Use stainless or coated driver bit to avoid iron transfer and surface rust stains