PRODUCT

Material: Stainless steel 304

Finish: Plain

Standard: ISO14581

Certification: ISO9001

MOQ:1000PCS

Samples: Free

Place of Origin: Zhejiang China

Product Details

Stainless steel Round head Self-tapping screws

Description:

| Name | Stainless steel Round head Self-tapping screws |

| Place of Origin | Jiaxing, Zhejiang, China |

| Dimension | M5-M20 |

| Surfance | plain |

| Material | stainless steel |

| Standard | DIN |

| Non-standards | OEM is available, according to drawing or samples |

| Samples | Samples are free. |

| Package | Pack the box first and put it in the carton, or according to customers' requirement. |

| Payment | T/T or L/C |

| 304 Chemical Composition(%) | ||||||||

| Grade | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | N≤ |

| 0.08 | 2 | 0.75 | 0.03 | 0.045 | 18.0-20.0 | 8.0-10.5 | 0.1 | |

| 304 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | Hardness(HB)(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200 |

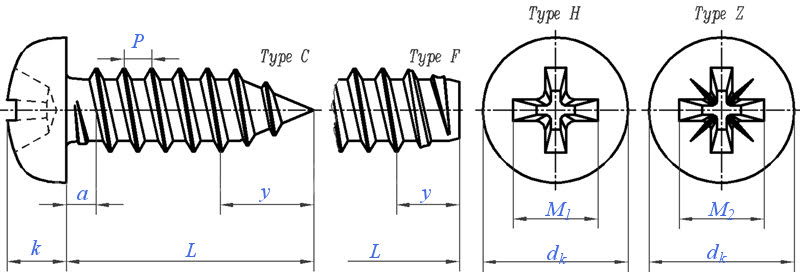

| 螺纹规格 | ST2.2 | ST2.9 | ST3.5 | (ST3.9) | ST4.2 | ST4.8 | ST5.5 | ST6.3 | ||||

| d | ||||||||||||

| P | 螺距 | 0.8 | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | |||

| a | 最大值 | 0.8 | 1.1 | 1.3 | 1.3 | 1.4 | 1.6 | 1.8 | 1.8 | |||

| dk | 最大值=公称 | 4.2 | 5.6 | 6.9 | 7.5 | 8.2 | 9.5 | 10.8 | 12.5 | |||

| 最小值 | 3.9 | 5.3 | 6.54 | 7.14 | 7.84 | 9.14 | 10.37 | 12.07 | ||||

| k | 最大值=公称 | 1.8 | 2.2 | 2.6 | 2.8 | 3.05 | 3.55 | 3.95 | 4.55 | |||

| 最小值 | 1.55 | 1.95 | 2.35 | 2.55 | 2.75 | 3.25 | 3.65 | 4.25 | ||||

| y | 最大值 | C型 | 2 | 2.6 | 3.2 | 3.5 | 3.7 | 4.3 | 5 | 6 | ||

| F型 | 1.6 | 2.1 | 2.5 | 2.7 | 2.8 | 3.2 | 3.6 | 3.6 | ||||

| 槽号 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | ||||

| M1 | ≈ | 2.6 | 3 | 4.2 | 4.4 | 4.6 | 5 | 6.5 | 7.1 | |||

| M2 | ≈ | 2.4 | 2.9 | 3.9 | 4.1 | 4.3 | 4.7 | 6.2 | 6.7 | |||

| 千件钢制重≈kg | - | - | - | - | - | - | - | - | ||||

Standard export packing or According to customer's requirement

Q:What is your main products?

A:Fasteners, Bolt, nut, screws, washer, threaded rod, anchors, self tapping screws, self driling screws, stainless steel plate, etc.

Q: What is your delivery time?

A:It depends on if we have stock or not, if we have stock goods, we can delivery within 2 days after receive the payment. And normally our production is in 20-30 days for one container (20-26 ton) products.

• Material: A2-70 & A4-70 stainless steel—≥ 700 MPa tensile, ≥ 450 MPa yield; salt-spray > 1 000 h (ASTM B117) .

• Head: Pan (round) shape with smooth curved top—large contact area prevents pull-through in thin panels and gives an attractive finish.

• Drive: Phillips cross recess No. 1 – No. 3—high bit engagement, no cam-out, fits every standard PH bit on the market.

• Thread: Type-A (wide-pitch) for sheet metal, Type-AB (fine) optional; sharp 45° gimlet point for fast start and low drive torque.

• Finish: Bright polished & passivated; optional sand-blast, DACRO® or Ruspert® coating on request.

• Temperature Range: –40 °C to +300 °C with full corrosion resistance.

• Re-usable: Threads stay intact after 20+ cycles in steel or hardwood.

Diameter: #4 (2.9 mm) – #14 (6.3 mm) / ST2.9 – ST6.3

Length: 6 mm – 80 mm (1/4" – 3-1/4")

Head Ø: 5.6 mm – 12.5 mm (≈ 2 × nominal dia.)

Standard: DIN 7981 / ISO 7049 (pan head self-tapping)

Certifications: RoHS, REACH, SGS salt-spray & mechanical report included.

-

Use a Phillips bit of matching size (PH1 for #4–#6, PH2 for #8–#10, PH3 for #12–#14).

-

2.5 mm pilot in hardwood; 0.8 × root diameter in steel ≤ 1 mm; none needed in plastic.

-

Drive at 1 000–1 500 rpm—pan head will seat flush without overdriving.

-

When fastening stainless to aluminum, use a nylon or EPDM washer to prevent galvanic corrosion.