PRODUCT

Material: Stainless steel 304

Finish: Passivation

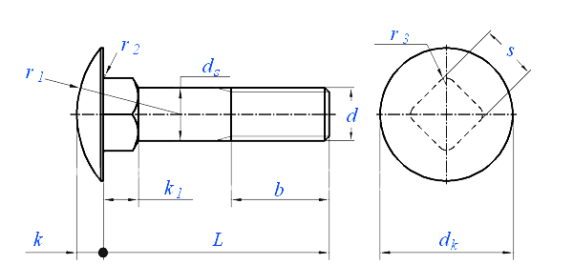

Standard: DIN603

Certification: ISO9001 SGS

MOQ:1000PCS

Samples: Free

Place of Origin: Zhejiang China

Product Details

Carriage Bolts are often used for connecting wood to wood, wood to metal and metal to metal。

At the Goshen hardware , we provide you with several high quality Carriage Bolts that are made from premium quality materials and different grades of stainless steel to ensure that these will last for long time.

Typically, carriage bolt sizes range from #10 to 3/4" or M5 to M20 in diameter while lengths span from about 1/2" to 20"—only larger sizes are available in long lengths. Measure length from under the head to the threaded end of the bolt. And it’s often using standard as beloW: DIN607, DIN603 ,ISO 8677,JIS B 1171,ASME/ANSI B 18.5.2.3M,ASME/ANSI B 18.5 ect.If u have drawing of carriage bolt, pls send it to us , we can according your requirement to production. Welcome your inquiry.

| 304 Chemical Composition(%) | ||||||||

| Grade | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | N≤ |

| 0.08 | 2 | 0.75 | 0.03 | 0.045 | 18.0-20.0 | 8.0-10.5 | 0.1 | |

| 304 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | Hardness(HB)(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200 |

| DIN603 | |||||

| Bolt Thread d | Pitch P | k | s | ||

| min | max | min | max | ||

| M5 | 0.8 | 2.7 | 3.3 | 4.52 | 5.48 |

| M6 | 1 | 3.12 | 3.88 | 5.52 | 6.48 |

| M8 | 1.25 | 4.12 | 4.88 | 7.42 | 8.58 |

| M10 | 1.5 | 4.62 | 5.38 | 9.42 | 10.58 |

| M12 | 1.75 | 6.05 | 6.95 | 11.3 | 12.7 |

| M16 | 2 | 8.05 | 8.95 | 15.3 | 16.7 |

| M20 | 2.5 | 9.95 | 11.05 | 19.16 | 20.84 |

• Austenitic stainless steel: A2-70 (AISI 304) or A4-70 / A4-80 (AISI 316 / 316L).

• Optional duplex 2205 or high-alloy 904L for maximum chloride resistance.

• Full traceability: EN 10204 3.1 mill certificate, heat number, and chemical analysis.

• Metric sizes: M5 – M20, lengths 12 mm – 300 mm per DIN 603 / ISO 8678.

• Imperial sizes: 1/4" – 3/4", lengths 1/2" – 12" per ASME B18.5.

• Square neck: 1.25 × bolt diameter (DIN 603) or 1.00 × diameter (ASME B18.5) to prevent rotation.

• Thread: standard 6g (metric) / 2A (UNC/UNF) right-hand; fine-pitch or left-hand available.

• Partial thread length: ≈ 2 × diameter under head; fully threaded on request.

• Tensile strength: 700 MPa (A2-70) / 800 MPa (A4-80) minimum.

• Yield strength: 450 MPa (A2-70) / 600 MPa (A4-80).

• Elongation: ≥ 40 %.

• Salt-spray resistance: > 1,000 h per ASTM B117 without red rust.

• Operating temperature range: –196 °C to 800 °C (304/316); duplex grades up to 315 °C.