PRODUCT

Material: Stainless steel

Finish: Plain

Standard: DIN933

Certification: ISO9001

MOQ:1000PCS

Samples: Free

Place of Origin: Zhejiang China

Product Details

|

Stainless Steel Hex Bolt |

|||

|

Standard: |

DIN933 |

||

|

Size: |

M5-M36 |

||

|

Material: |

Duplex stainless steel 2205 |

||

|

Thread: |

METRIC |

||

|

Finish: |

Plain,Nickel, Chrome |

||

|

Packing: |

bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand |

||

|

Trade Term: |

FOB/CIF/CFR/CNF/EXW/DDU/DDP |

||

|

Payment |

T/T, L/C |

||

|

Market: |

South&north Amrica/Europe/East&South east Asia/ Australia and ect. |

||

|

Our advantage: |

One-stop shopping; High quality; Competitive price; Timely delivery; Technical support; Supply Material and Test Reports;

|

||

| 2205Chemical component | ||||||||

| Grade | C≤ | Mn≤ | Si≤ | Mo | P≤ | Cr | Ni | N |

| 0.03 | 2.0 | 1.0 | 2.5-3.5 | 0.045 | 21.0-23.0 | 4.5-6.5 | 0.08-0.2 | |

| 2205 Mechanical property | |||

| σb≥ | σb≥ | δ≥ | HB[N(kgf/mm2)] |

| 795(Mpa) | 550(Mpa) | 15% | ≤310(HB) |

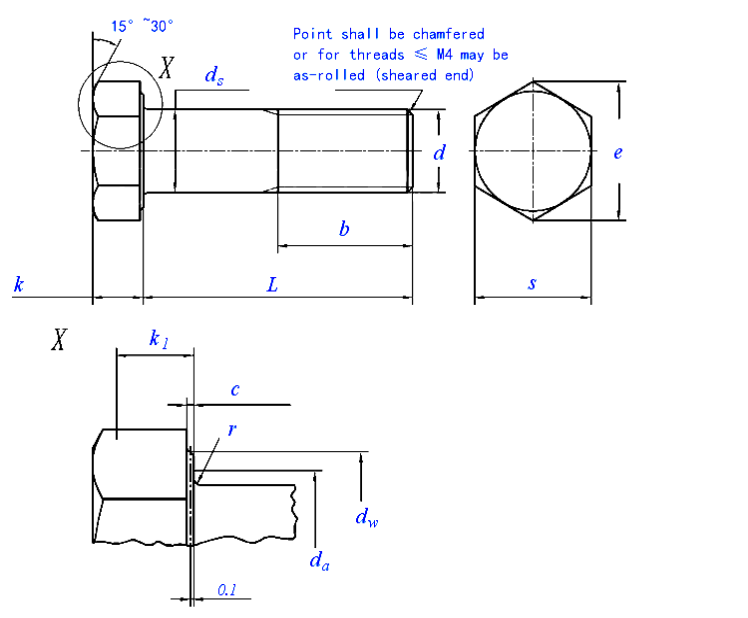

| DIN931 | ||||||||||||||

| Screw Thread d | P | b | c | k | s | |||||||||

| Thread Pitch | L≤125 | 125<L≤200 | L>200 | min | max | Nominal Size | Grade A | Grade B | max | Grade A | Grade B | |||

| min | max | min | max | min | min | |||||||||

| M5 | 0.8 | 16 | 22 | - | 0.15 | 0.5 | 3.5 | 3.35 | 3.65 | - | - | 8 | 7.78 | - |

| M6 | 1 | 18 | 24 | - | 0.15 | 0.5 | 4 | 3.85 | 4.15 | - | - | 10 | 9.78 | - |

| (M7) | 1 | 20 | 26 | - | 0.15 | 0.5 | 4.8 | 4.65 | 4.95 | - | - | 11 | 10.73 | - |

| M8 | 1.25 | 22 | 28 | - | 0.15 | 0.6 | 5.3 | 5.15 | 5.45 | - | - | 13 | 12.73 | - |

| M10 | 1.5 | 26 | 32 | 45 | 0.15 | 0.6 | 6.4 | 6.22 | 6.58 | - | - | 17 | 16.73 | - |

| M12 | 1.75 | 30 | 36 | 49 | 0.15 | 0.6 | 7.6 | 7.32 | 7.68 | - | - | 19 | 18.67 | - |

| (M14) | 2 | 34 | 40 | 53 | 0.15 | 0.6 | 8.8 | 8.62 | 8.98 | - | - | 22 | 21.67 | - |

| M16 | 2 | 38 | 44 | 57 | 0.2 | 0.8 | 10 | 9.82 | 10.18 | 9.71 | 10.29 | 24 | 23.67 | 23.16 |

| (M18) | 2.5 | 42 | 48 | 61 | 0.2 | 0.8 | 11.5 | 11.28 | 11.72 | 11.15 | 11.85 | 27 | 26.67 | 26.16 |

| M20 | 2.5 | 46 | 52 | 65 | 0.2 | 0.8 | 12.5 | 12.28 | 12.72 | 12.15 | 12.85 | 30 | 29.67 | 29.16 |

| (M22) | 2.5 | 50 | 56 | 69 | 0.2 | 0.8 | 14 | 13.78 | 14.22 | 13.65 | 14.35 | 32 | 31.61 | 31 |

| M24 | 3 | 54 | 60 | 73 | 0.2 | 0.8 | 15 | 14.78 | 15.22 | 14.65 | 15.35 | 36 | 35.38 | 35 |

| (M27) | 3 | 60 | 66 | 79 | 0.2 | 0.8 | 17 | - | - | 16.65 | 17.35 | 41 | - | 40 |

| M30 | 3.5 | 66 | 72 | 85 | 0.2 | 0.8 | 18.7 | - | - | 18.28 | 19.12 | 46 | - | 45 |

| (M33) | 3.5 | 72 | 78 | 91 | 0.2 | 0.8 | 21 | - | - | 20.58 | 21.42 | 50 | - | 49 |

| M36 | 4 | 78 | 84 | 97 | 0.2 | 0.8 | 22.5 | - | - | 22.08 | 22.92 | 55 | - | 53.8 |

• Metric: M3 – M64, lengths 6 mm – 500 mm; threads per ISO 4014 (partial thread) or ISO 4017 (full thread).

• Imperial: #10 – 2-1/2", lengths 1/2" – 20" per ASME B18.2.1.

• Thread class: 6g (metric) / 2A (UNC, UNF). Fine-pitch, left-hand, or ACME threads available.

• Hex head width and height strictly follow ISO 4032 / ASME B18.2.2 tolerances.

• Tensile strength: 500 MPa (A2-50) up to 800 MPa (A4-80).

• Yield strength: 210 – 600 MPa, grade dependent.

• Hardness: 70 – 95 HRB (A2/A4), 28 – 38 HRC (2205 duplex).

• Proof load tested at 1.1 × working load; 100 % magnetic permeability < 1.05 for austenitic grades.

• Salt-spray performance: > 1,000 h per ASTM B117 without red rust.

• Pitting Resistance Equivalent Number (PREN) ≥ 24 (304) and ≥ 32 (316).

• Resistant to chlorides, acids, alkalis, and marine atmospheres; suitable for –196 °C to 800 °C service.