PRODUCT

Material: Stainless steel 316

Grade: A4-80

Finish: Plain

Standard: DIN6921

Certification: ISO9001

MOQ:1000PCS

Samples: Free

Place of Origin: Zhejiang China

Product Details

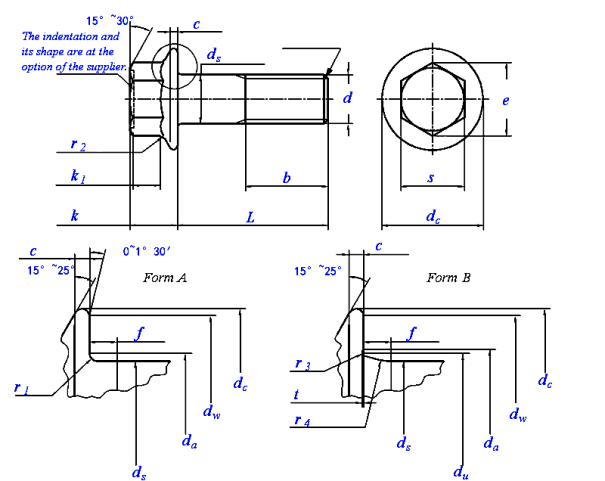

A4-80 hexagon flange bolts din6921

Flange bolts have a circular edge under the head that acts like a washer to distribute loads. Standard, non-serrated flange bolts are also called frame bolts. Flange bolts are used in automobiles to secure outer casings protecting engines and transmissions. In plumbing, they secure pipe ends to ensure strong hold, regardless of materials in the ducts. Serrated flange bolts have teeth that grip surfaces for a tight hold. In electronics, flange bolts hold components together tightly to prevent particles from getting into devices. In hard-to-reach areas, flange bolts help install decks and overhead attachments more easily than regular bolts and washers. Long flange bolts are used to construct oil rigs, energy plants, and ships.

| 316 Chemical Composition(%) | ||||||||||

| Grade | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | Cu | MO | N |

| 0.017 | 0.98 | 0.25 | 0.0016 | 0.0414 | 16.23 | 10.08 | 0.32 | 2.06 | 0.037 | |

| 316 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | Hardness(HB)(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200 |

| DIN6921 | ||||||

| Screw Thread d | Pitch P | k | s | |||

| coarse thread | Fine therad-1 | Fine thread-2 | min | max | ||

| M6 | 1 | / | / | 6.6 | 9.78 | 10 |

| M8 | 1.25 | 1 | / | 8.1 | 12.73 | 13 |

| M10 | 1.5 | 1.25 | 1 | 9.2 | 14.73 | 15 |

| M12 | 1.75 | 1.5 | 1.25 | 11.5 | 15.73 | 16 |

| M14 | 2 | 1.5 | / | 12.8 | 17.73 | 18 |

| M16 | 2 | 1.5 | / | 14.4 | 20.67 | 21 |

• Standard: DIN 6921, ISO 4162, or ASME B18.2.1 (customizable)

• Material: A2-70 (AISI 304) or A4-80 (AISI 316) stainless steel

• Size Range: M5 – M20 (¼" – ¾" UNC/UNF available)

• Length: 10 mm – 200 mm; longer specials on request

• Thread: Metric coarse 6g default; fine pitch, left-hand, or inch threads optional

• Flange Diameter: e.g., M8 ≈ 16.8 mm | M10 ≈ 21.2 mm

• Head Height: same as standard hex head for standard sockets

• Proof Load: A2-70 ≥ 450 MPa | A4-80 ≥ 600 MPa

• Core Hardness: ≤ 32 HRC

• Salt-Spray: A2 ≥ 500 h | A4 ≥ 1 000 h

• Temperature Range: –50 °C to +300 °C (non-magnetic at ambient)

• Integral flange spreads clamp load, preventing damage to mating surfaces and reducing part count

• Smooth or serrated flange underside options for anti-vibration locking

• Zero coating build-up preserves precise grip length and fits standard hex tools

• Non-corroding stainless finish eliminates future maintenance and meets hygiene requirements