PRODUCT

Material: Carbon steel

Finish:blue-white zinc plated

MOQ:1000PCS

Samples: Free

Standard:Non-standard , drawing or samples

Product Details

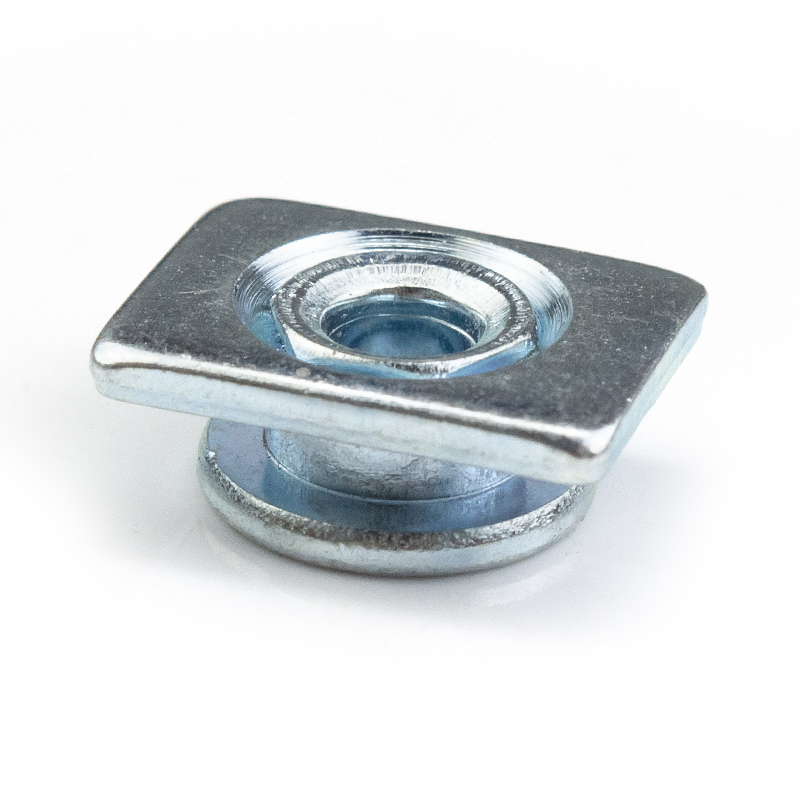

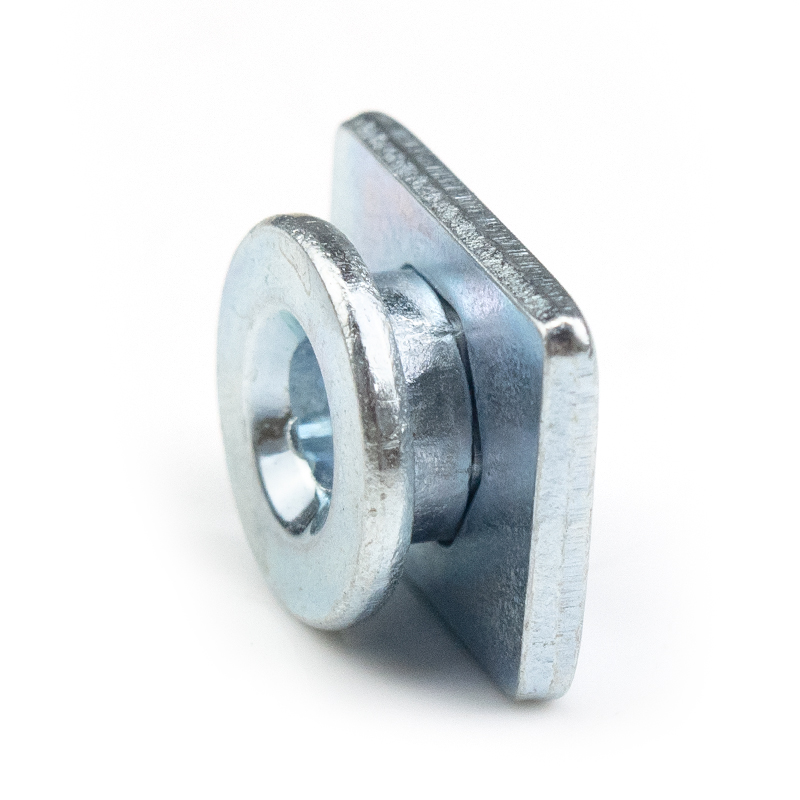

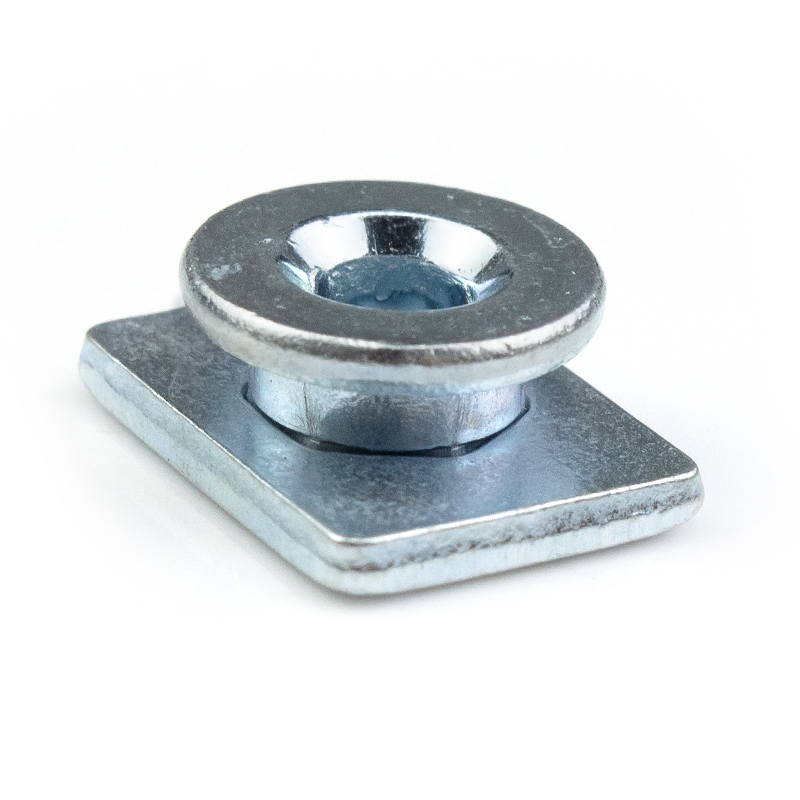

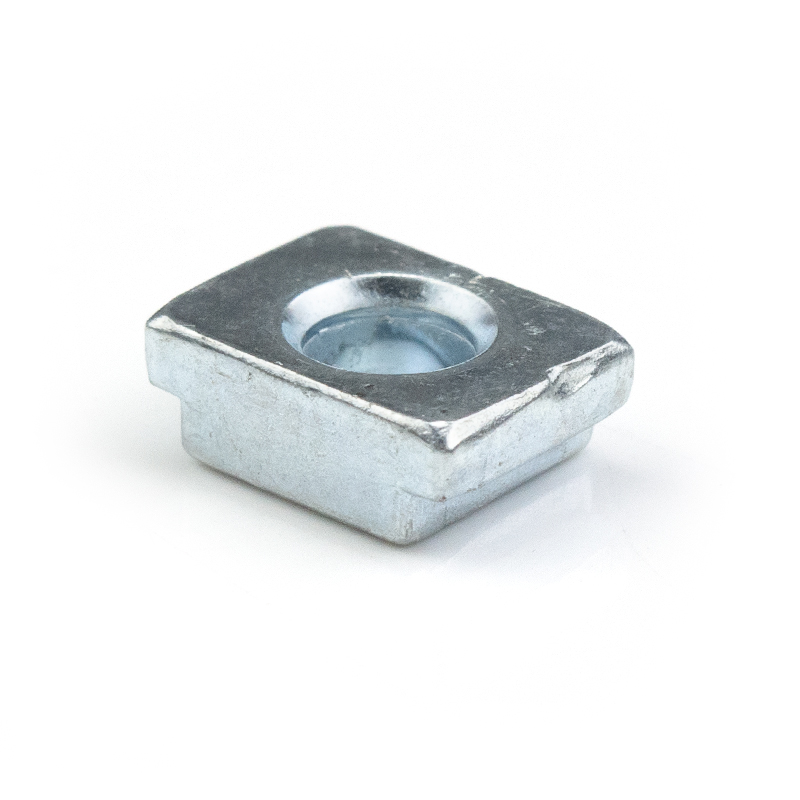

This is a custom-made hexagonal square base plate combination nut. It is made of carbon steel or stainless steel through cold heading and welding assembly processes, and its surface is treated with environmentally friendly blue-white zinc plating or left in its original color. The product structure consists of two parts: the upper part is a circular nut head with internal hexagonal holes, providing standard tool interfaces and an attractive decorative surface; the lower part is a square plate base, offering a large flat surface for support and anti-rotation limiting functions. The upper and lower parts are formed as a single unit through welding or mechanical riveting, combining the tightening function of the nut with the pressure dispersion effect of the washer, and is specially designed for thin plates, brittle materials, or special connection scenarios requiring a large bearing surface. The non-standard customization feature allows for flexible adjustment of the square plate size, nut height, and thread specifications to achieve a perfect match with the specific structure of the workpiece.

Hexagon socket blind hole design

The top of the nut has a standard hexagon hole with an appropriate depth, which can accommodate the bolt head to be fully inserted or flush with the surface of the nut, avoiding exposed protrusions that could cause scratches or affect appearance. The hexagon specification matches the thread diameter, ensuring sufficient space for the wrench operation.

Large flat square base plate

The side length of the square base plate is usually 1.5 to 2 times the diameter of the nut head, providing a much larger bearing area than ordinary hexagonal nuts or flange nuts, effectively reducing the pressure per unit area and protecting the soft or brittle substrate from being crushed.

Anti-turning limit function

The square base plate can be inserted into pre-made square holes or grooves, or rely on the friction between the four corners and the surface of the workpiece to prevent wobbling during tightening, enabling one-sided operation without the need to use tools to fix on the back, especially suitable for assembly in enclosed cavities.

Integrated modular structure

The nut head and base plate are permanently connected through resistance welding, laser welding or mechanical riveting, with a strength higher than the simple combination of nut and washer, and avoiding assembly errors such as missing or mismatched washers.

Transition rounded corner reinforcement

A natural transition rounded corner or welding reinforcement rib is provided at the junction of the nut head and the base plate to eliminate stress concentration and prevent the head from tearing off and falling off from the base plate when subjected to large pulling force.

Protecting fragile substrates

For materials with low compressive strength such as fiberglass reinforced plastic, carbon fiber boards, engineering plastics, and gypsum boards, the large base plate distributes the load centrally to a larger area, preventing local crushing and cracking, and improving connection reliability by more than three times.

Simplifying assembly processes

Instead of the traditional three-piece assembly of nuts, washers, and spring washers, this design reduces the number of material types and assembly steps, making BOM management more concise, improving production line operation efficiency, and eliminating the quality risk of missing washers.

Enhanced anti-loosening performance

The friction torque between the square base plate and the surface of the workpiece effectively resists the torque causing the thread to loosen. It maintains the pre-tightening force under vibration conditions and can replace some anti-loosening nut applications at a lower cost.

Ensuring appearance consistency

The internal hexagonal counterbore design makes the bolt head flush with or slightly lower than the surface of the nut, and the exposed surface is regular and aesthetically pleasing, suitable for consumer electronic products or decorative structures with appearance requirements.

Flexible customization for adaptation

The shape of the base plate can be customized to be rectangular, circular, rhombic, or with notches, and the thread specification, nut height, and base plate thickness can be independently adjusted, perfectly meeting the requirements of non-standard structural design.

Composite material structures

Assembly and connection of carbon fiber or fiberglass components such as wind turbine blades, unmanned aircraft fuselages, and car bumpers. The large base plate prevents delamination and damage of the laminated board.

Electronic and electrical enclosures

Thin steel plates or aluminum plates for server cabinets, distribution cabinets, and instrument housings. Hexagonal nuts facilitate disassembly and maintenance in compact spaces.

Building decorative materials

Post-installed installation of aluminum single-panel curtain walls, GRG ceilings, and acrylic signs. This disperses point loads to prevent deformation and cracking of the decorative panels.

Railway interior decoration

Wall panels and roof panels of high-speed train carriages and subway vehicles. Fixed with meeting vibration and fireproof requirements. Stainless steel material is optional.

Medical equipment and devices

Clean connection of plastic shells and aluminum frame structures. Non-magnetic stainless steel version is suitable for equipment around nuclear magnetic resonance.

Amusement facility manufacturing

Hardware connection points for fiberglass slides and swing seats. Large base plate ensures structural safety under long-term dynamic loads.