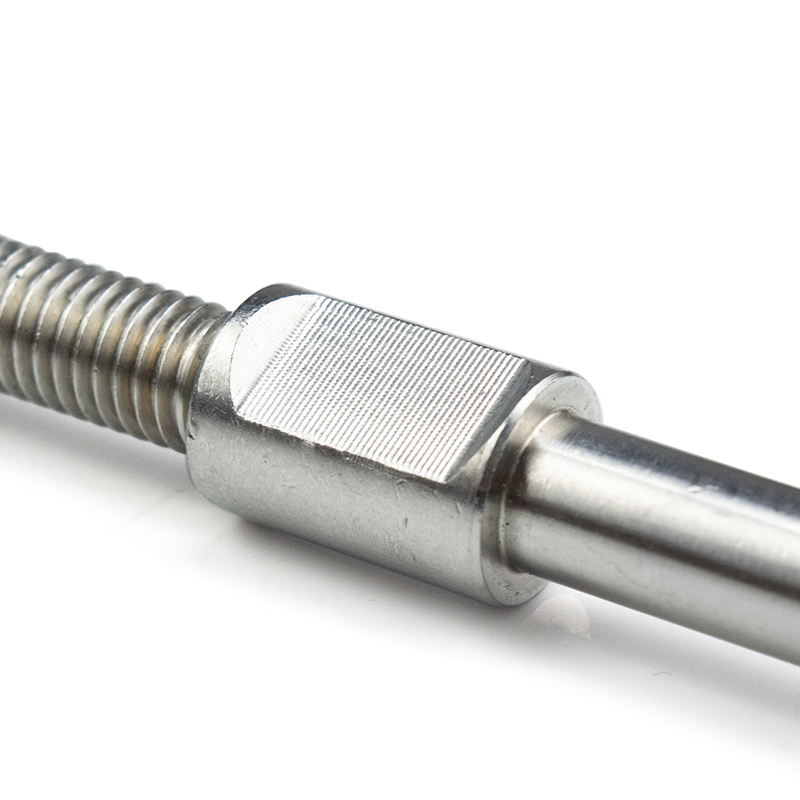

PRODUCT

Material: stainless steel

Finish: plain

Samples: Free

Standard:Non-standard , drawing or samples

Product Details

Cold forging parts are precision-engineered components manufactured through a cold forming process. This method involves shaping metal at room temperature using high pressure and specialized dies. The result is a high-strength, dimensionally precise part with excellent surface finish and minimal material waste. Cold forging is ideal for producing small to medium-sized parts with complex geometries and tight tolerances. Our cold forging parts are designed to meet the highest standards of quality and performance, making them suitable for a wide range of industries and applications.

-

High Strength: The cold forming process results in a dense, uniform microstructure, enhancing the mechanical properties of the material.

-

Precision: Cold forging allows for tight tolerances and complex geometries, ensuring parts meet exact specifications.

-

Surface Finish: The process produces a smooth surface finish, reducing the need for secondary operations like machining or grinding.

-

Material Efficiency: Minimal material waste compared to traditional machining processes, making cold forging an environmentally friendly and cost-effective option.

-

Customization: Available in a variety of materials and custom shapes to meet specific application needs.

-

Consistency: High repeatability ensures consistent quality across large production volumes.

-

Materials: Stainless steel, carbon steel, aluminum, brass, and other ferrous and non-ferrous metals.

-

Size Range: From small precision parts (a few millimeters) to medium-sized components (up to several centimeters).

-

Tolerances: ±0.05 mm or tighter, depending on the specific requirements.

-

Surface Finish: Ra 0.8 µm or better, suitable for applications requiring a smooth surface.

-

Custom Options: Custom shapes, sizes, and finishes available upon request.

-

Automotive: Used in engine components, transmission parts, and suspension systems where high strength and precision are critical.

-

Aerospace: Ideal for lightweight, high-strength parts in aircraft engines, landing gear, and structural components.

-

Electronics: Suitable for small, precision components in electronic devices and consumer electronics.

-

Medical Equipment: Used in medical devices and instruments where precision and reliability are paramount.

-

Industrial Machinery: Provides durable and precise parts for various industrial applications, including gears, shafts, and connectors.

-

Consumer Goods: Used in high-volume production of parts for appliances, tools, and other consumer products.