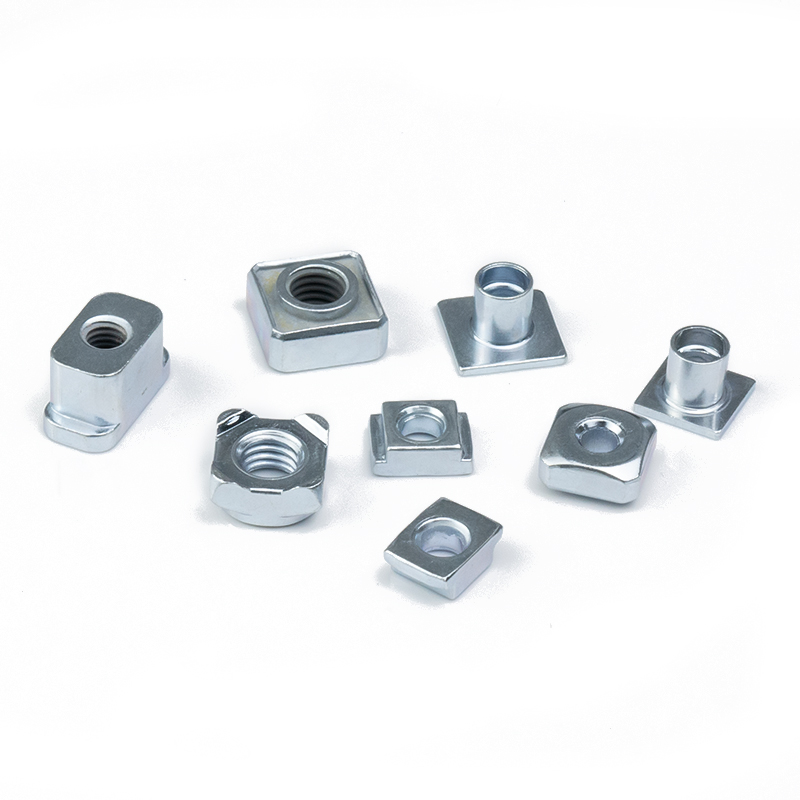

PRODUCT

Material: Carbon steel

Finish: Plain;Galvanized

Standard:Non

MOQ:1000PCS

Samples: Free

Place of Origin: Zhejiang China

Product Details

Customized fasteners, also known as non-standard fasteners, are specially designed and manufactured to meet unique specifications that do not conform to standard industry dimensions or configurations. These fasteners are essential in applications where standard fasteners cannot satisfy specific requirements for safety, performance, or functionality.

1.Standard Reference: Based on DIN 934 / ISO 4032 hex nut, width across flats 1.5 D, height 0.8 D.

2.Non-Standard Variant: Width enlarged to 28 mm, height extended to 16 mm, 30° chamfer added on bearing face for seal washer seating.

3.CNC Precision: Hex milled on 5-axis VMC, width tolerance ±0.05 mm, thread 6H, 100 % ring-gauge inspection.

4.Customization Limits: Size range M3×0.5 – M24×3.0; ultra-thin flange 0.2 mm or micro-inner chamfer 0.5 mm achievable for optical housings.

-

Stainless Steel: Offers excellent corrosion resistance and is suitable for harsh environments.

-

Aluminum Alloy: Lightweight and strong, ideal for applications where weight reduction is crucial.

-

Titanium Alloy: Provides high strength-to-weight ratio and corrosion resistance, often used in aerospace and marine applications.

-

Nickel Alloys: Resistant to high temperatures and corrosive environments, suitable for extreme conditions.

-

Brass and Copper: Good electrical and thermal conductivity, used in electrical and plumbing applications.

-

Base Steel: C45 / 1045 medium-carbon steel, core hardness 22-28 HRC after quench & temper.

Strength Class: Oil-quenched 880 °C + tempered 480 °C, meets Class 8 proof load ≥ 800 MPa.

Toughness: Charpy KV2 ≥ 27 J at –20 °C, suitable for outdoor PV tracker struts.

Alternatives: Free-cutting 1215MS or 40Cr alloy steel available to upgrade to Class 10 without size change.

-

Customized fasteners can vary significantly in design, including unique shapes, sizes, thread patterns, and head styles. They are often tailored to fit specific mechanical assemblies or to withstand particular environmental conditions. Specifications may include custom lengths, diameters, tolerances, and mechanical properties such as tensile strength and shear strength.

-

CNC Machining: Allows for high precision and tight tolerances, suitable for complex geometries.

-

Forging: Used for high-strength applications, providing superior mechanical properties.

-

3D Printing: Enables the creation of intricate designs that are difficult to achieve with traditional methods.

-

Thread Rolling: Produces accurate thread forms with improved surface finish and strength.