PRODUCT

Material: carbon steel

Finish: yellow zinc plated

Certification: ISO9001

MOQ:1000PCS

Samples: Free

Place of Origin: Zhejiang China

Product Details

Yellow zinc plated concrete drilling screws

Description:

| Name | 7.5mm x 202mm torx Concrete Screws |

| Place of Origin | Jiaxing, Zhejiang, China |

| Dimension | 7.5x202mm |

| Surfance | zinc plated/white/yellow |

| Material | Carbon steel |

| Standard | DIN, AISI, ASME, ISO |

| Non-standards | OEM is available, according to drawing or samples |

| Samples | Samples are free. |

| Package | Pack the box first and put it in the carton, or according to customers' requirement. |

| Payment | T/T or L/C |

Self Drilling screw can also be called drilling self-tapping self-drilling screw, drilling screw, self-drilling screw, dovetail screw, and the tail of drilling tail screw screw shows drilling tail or sharp tail, no need for auxiliary processing can be directly in the setting of materials, basic materials drilling, tapping, locking, can greatly save construction time.

| 316 Chemical Composition(%) | ||||||||

| Grade | C≤ | Mn≤ | P≤ | S≤ | Si≤ | Ni | Cr | Mo |

| 0.08 | 2.00 | 0.045 | 0.030 | 1 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | |

| 316 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | Hardness(HB)(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200 |

Standard export packing or According to customer's requirement

Q:What is your main products?

A:Fasteners, Bolt, nut, screws, washer, threaded rod, anchors, self tapping screws, self driling screws, stainless steel plate, etc.

Q: What is your delivery time?

A:It depends on if we have stock or not, if we have stock goods, we can delivery within 2 days after receive the payment. And normally our production is in 20-30 days for one container (20-26 ton) products.

• Material: Hardened 1022A carbon steel, heat-treated to HRC 32–39

• Finish: Yellow-zinc electro-plated 5–8 µm, trivalent chromate passivation, 72 h salt-spray protection

• Head: Countersunk flat (CSK) 90°, flush finish

• Drive: Phillips #2 or Torx T25 for high-torque, low-cam-out installation

• Threads: UNC-2A, twin-lead design for fast engagement

• Drill Point: #2/#3 self-driller drills, taps and fastens in one pass through steel ≤ 6 mm (12–14 ga)

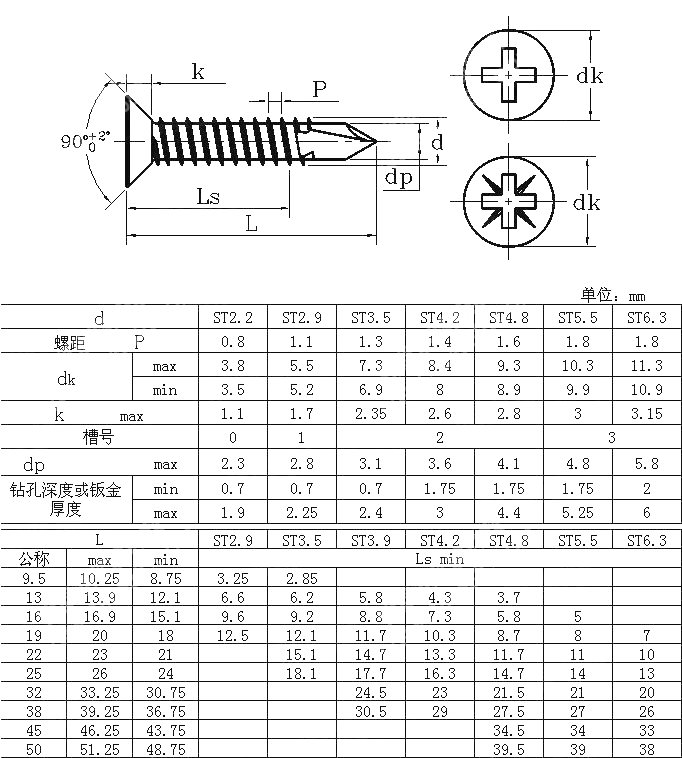

• Sizes: #6×3/4" up to #14×6" (3.5 mm–6.3 mm Ø, 19 mm–152 mm length)

• Pull-out strength ≥ 1.2 kN in 2 mm steel

• Shear strength ≥ 2.5 kN

• Drill speed: 1,800–2,500 rpm recommended for 0.8–6 mm substrate

• Corrosion rating: 6+ years indoor, 3–5 years outdoor sheltered

• Roofing & wall cladding to light-gauge steel purlins

• HVAC ductwork fastening to galvanized framing

• Electrical enclosures, control panels & switchgear

• Modular steel-frame buildings, prefab warehouses