PRODUCT

Material: Stainless steel 304

Grade: A2-70,A2-80

Finish: Plain

Standard: DIN6921

Certification: ISO9001

MOQ:1000PCS

Samples: Free

Place of Origin: Zhejiang China

Product Details

Flange bolts are composed of hexagonal heads and flanges. The "ratio of supporting area to stress area" is larger than that of ordinary bolts. Therefore, this type of bolt can withstand higher pre-tightening force and has better anti-loosening performance, so it is widely used. Used in automobile engines, heavy machinery and other products.

| Jiaxing Goshen Hardware Co.Ltd | ||||||||

| Name | Flanger Bolt | Material | Stainless Steel 304 | |||||

| Standard | ANSI/SIME,DIN, OEM | Surface | Plain | |||||

| Size | M5-M20 | Package | Standard marine packaging | |||||

| Stock | Regualar Have In Stock | Head Mark | Can be Customized By Buyer | |||||

| Export Region | Europe,North America,Middle East and More other | |||||||

| 304 Chemical Composition(%) | ||||||||

| Grade | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | N≤ |

| 0.08 | 2 | 0.75 | 0.03 | 0.045 | 18.0-20.0 | 8.0-10.5 | 0.1 | |

| 304 Mechanical property | |||

| σb≥ | σ0.2≥ | δ5 (%)≥ | HB[N(kgf/mm2)] |

| 520(Mpa) | 205(Mpa) | 40% | ≤187 HRB≤90 HV ≤200 |

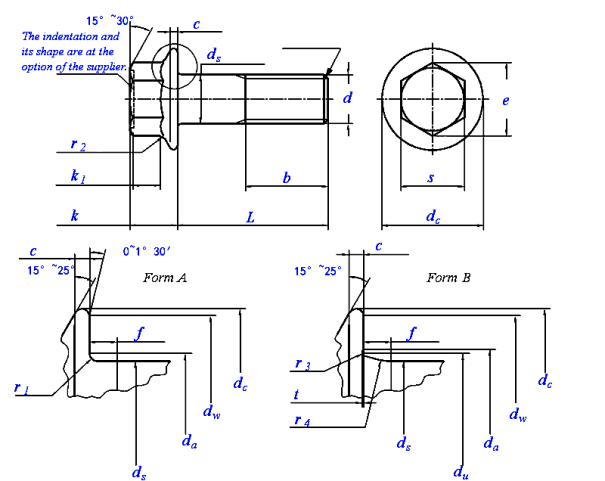

| 螺纹规格 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M20 | ||||

| d | ||||||||||||

| P | 螺距 | Coarse Thread | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | ||

| Fine Thread 1 | / | / | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 1.5 | ||||

| Fine Thread 2 | / | / | / | 1 | 1.25 | / | / | / | ||||

| b | L≤125 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 46 | |||

| 125<L≤200 | / | / | 28 | 32 | 36 | 40 | 44 | 52 | ||||

| L>200 | / | / | / | / | / | / | 57 | 65 | ||||

| c | MAX | 1 | 1.1 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | |||

| da | A | MAX | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 22.4 | ||

| B | MAX | 6.2 | 7.4 | 10 | 12.6 | 15.2 | 17.7 | 20.7 | 25.7 | |||

| dc | MAX | 11.8 | 14.2 | 18 | 22.3 | 26.6 | 30.5 | 35 | 43 | |||

| ds | MAX | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | |||

| MIN | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 19.67 | ||||

| du | MAX | 5.5 | 6.6 | 9 | 11 | 13.5 | 15.5 | 17.5 | 22 | |||

| dw | MIN | 9.8 | 12.2 | 15.8 | 19.6 | 23.8 | 27.6 | 31.9 | 39.9 | |||

| e | MIN | 8.71 | 10.95 | 14.26 | 16.5 | 17.62 | 19.86 | 23.15 | 29.87 | |||

| f | MAX | 1.4 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | |||

| k | MAX | 5.4 | 6.6 | 8.1 | 9.2 | 11.5 | 12.8 | 14.4 | 17.1 | |||

| k1 | MIN | 2 | 2.5 | 3.2 | 3.6 | 4.6 | 5.1 | 5.8 | 6.8 | |||

| r1 | MIN | 0.25 | 0.4 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.8 | |||

| r2 | MAX | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.9 | 1 | 1.2 | |||

| r3 | MIN | 0.1 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | |||

| r4 | ≈ | 3 | 3.4 | 4.3 | 4.3 | 6.4 | 6.4 | 6.4 | 8.5 | |||

| s | MAX=Metric | 8 | 10 | 13 | 15 | 16 | 18 | 21 | 27 | |||

| MIN | 7.78 | 9.78 | 12.73 | 14.73 | 15.73 | 17.73 | 20.67 | 26.67 | ||||