VIDEO & CENTER

Hexagon bolts are widely used in the fastener industry at present, compared with the monotype and cross head, its assembly is not easy to slip teeth, and the torque is higher. Compared with dodecagonal head and multi-tooth head, it has simple structure and low cost. Therefore, the comprehensive price of hexagonal bolts is higher, and it is also the type of bolts used most in automobiles.

Hexagon bolts can be divided into hexagon bolts and outer hexagon bolts. What are the differences between these two bolts? How to choose when applying?

01 Structure

Structurally, hex bolts and hex bolts are easy to distinguish. There is basically no difference in the thread part, the outer hexagonal edge of the head is hexagonal, and the head is not dented. In order to increase the bearing area of the head, it can also be made into an outer hexagonal flange bolt, which is also widely used.

The outside of the head of the hex bolt is round, and the middle is a concave hexagon, the more common is the cylindrical head hex, and the pan head hex, the countersunk head hex, the flat head hex, the headless screw, the stop pay screw, the machine screw, etc., is called the headless hex.

Of course, hex bolts can also be made into hex flange bolts in order to increase the head contact area.

In order to control the friction coefficient of the bolt head or improve the anti-loosening performance, the outer hexagon combination bolt and the inner hexagon combination bolt can also be made.

02 Cost

The thread of the inner hexagon and outer hexagon bolts is generally made by rolling wire, and the rolling plate is basically the same, and there is no obvious difference in cost.

The difference point is the head manufacturing process, because the head structure is completely different, the need to use different molds and processes, the head manufacturing cost of the hex bolt is higher than the head manufacturing cost of the outer hex thread, the screw king understands that the cost of the outer hex bolt is only half of the hex bolt.

03 Tightening Tools

This can be divided into living and production assembly.

In the assembly of life, the wrench shape of the hex bolt is "L" type, one side is long and the other side is short, the short side is screwed, and the long side of the hand can save effort and tighten the screw better. The outer hexagonal bolt is a wrench with an equilateral hexagonal head, such as a flexible wrench, a box wrench, an open wrench, etc. As shown in the following figure, the old iron has done daily assembly or maintenance at home, and should be familiar with the following two tools.

Assembly in production, in order to ensure the tightening quality and automation requirements, will be assembled through a fixed torque wrench and high-precision tightening gun, so it is necessary to match the corresponding tightening sleeve, the sleeve of the outer hexagonal bolt is concave hexagonal, and the sleeve of the inner hexagonal bolt is convex hexagonal, as shown in the following figure, the two will have a series of dimensions matching sleeves according to the size of the bolt head.

04 Advantages and Disadvantages

4.1 Advantages

External hex bolts/screws: good self-locking; The preload contact area is large, and the preload force is large; Full thread length range is wider; There can be hinged holes, which can fix the position of parts and withstand shear caused by transverse forces; The head is thinner than the socket, and in some places the socket cannot be replaced.

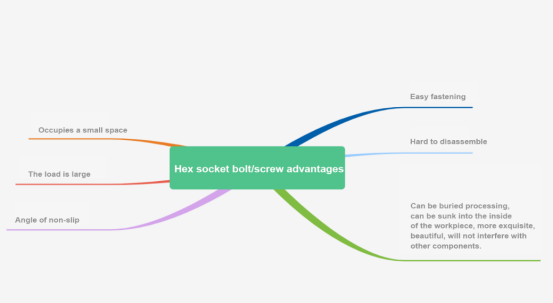

Hex bolts/screws: easy to tighten; Not easy to disassemble; Easy to slip Angle; Occupy a small space; The load is large; Can be buried processing, can be sunk into the inside of the workpiece, more exquisite, beautiful, will not interfere with other components.

4.2 Disadvantages

Outer hex bolts/screws: occupy a large space, more delicate occasions are not suitable; Cannot be used for sinking heads.

Hex bolts/screws: small contact area, small preload; No full thread over a certain length; Fastening tools are not well matched, easy to screw up and easy to replace; Disassembly to use a professional wrench, usually not good disassembly.

05 Application Scope

It is the advantages and disadvantages of the outer hexagon bolt and the inner hexagon bolt, so how to choose when applying?

If the axial force required by the tightening point is large, that is, the tightening torque is large, and the external tightening space is sufficient, use the outer hexagon bolt to tighten.

If the tightening position has space limitations, or there is a need to make a beautiful countersunk head, and the axial force required for the tightening point is not large, that is, the tightening torque is not large, then the hex can be made.

Take the car as an example, the sub-frame and the body connection position, several bolts through the bottom through the sub-frame, tighten to the body, because the bottom is invisible area, no aesthetic requirements, there is no interference in tightening, and the axial force and torque required for tightening is large (bolt over-yield tightening), for this connection position is suitable for the use of outer hexagon bolt tightening.

The connection of the interior trim parts is the customer's visual area, usually has aesthetic requirements, the need to do the counterweight structure, the top of the bolt head needs to be kept on a plane with the structure of the connected part, or the outside needs to add a layer of covering parts, and the tightening axial force and torque of such positions are also small. Therefore, it is very suitable for tightening with hex bolts or screws.

If you are not sure how to choose, it is necessary to see if the connection position has the requirements of exquisite, beautiful, and assembly space restrictions. If so, then choose hex bolts/screws. If not, choose the outer hex bolts/screws, after all, the outer hex bolts are cheaper, and other requirements can basically be met. This is why outer hex bolts/screws are more widely used than inner hex bolts/screws.

06 Experience and conclusion

Hexagon head bolts/screws are widely used in various industries because of their simple structure, easy to use, moderate price, tightening is not easy to fail, etc. Common hexagon head bolts/screws have two kinds of structures: outer hexagon and inner hexagon.

Structurally, the head structure of the two can be clearly distinguished; The cost of the outer hexagon is half the price of the inner hexagon bolt; Whether in life or in production, its tightening tools are different; According to the advantages and disadvantages of the two, in the application, if the connection position has the requirements of exquisite, beautiful, and assembly space limitation, the hex head bolt/screw is selected, if there is no such requirement, the outer hex head bolt/screw is selected.