VIDEO & CENTER

Screws, nuts, this kind of connected parts, widely used in our lives and industrial production, in our lives, you will not encounter such a situation, bicycle screws loose, or we use the pot of cooking screws fell down, this time you will definitely go to screw it! However, the general idea is that the screw should be screwed so far, always feel that the screw must be screwed the tighter the better, but is this really the case?

Tightening the screws is not always better

Generally, a screwed screw will be affected by two forces, one is downward, one is upward, the bolt rotates down the thread, and produces a downward axial force in the process of contact with the thread. At the same time, there is an upward force corresponding to the downward axial force, and this upward force is the distribution force generated by the contact between the nut and the lower plane. These two forces should balance each other.

Each screw has its specified torque, in the process of tightening the bolt, it will be infinitely close to a torque, and once the torque is destroyed, the bolt will easily enter the yield stage, and seriously it will cause the screw to break. Once the bolt enters the yield stage, it will produce permanent deformation, which is irreversible, that is to say, the bolt will fail. In real life, have you ever encountered such a situation, the screw is twisted and there is a trip phenomenon, the phenomenon of the trip is caused by this reason, and once the trip, it is impossible to screw on again, because the bolt has been permanently deformed, it can be seen that the bolt is not screwed tighter the better.

There is also a case that the bolt is returned half a circle after tightening, which can make the bolt and nut tighter. However, if the limit is broken when the bolt is screwed, once the yield stage is entered, the bolt has been deformed, at this time, it is meaningless to return half a circle, but if the degree of tightening does not break the limit, then it is not necessary to return half a circle, but it will make the bolt more loose.

When exactly do we need to go back half a circle?

When there is a gasket between the bolt and the nut, we need to return half a turn. Do not underestimate a thin piece of metal, it plays an important role in the bolted connection, the role of the washer is equivalent to a spring, its purpose is also to increase elasticity, increase elasticity is also to make the entire component stronger. However, as a spring assembly, the bearing capacity of the gasket is also limited. The so-called spring, that is, after extrusion, it will deform, and due to its own elasticity, it will recover after the pressure is eliminated, but the resilience of the spring is limited.

When the pressure on the gasket is too large to exceed the limit, the spring effect will disappear, so the existence of the gasket is redundant.

In order to maintain the elastic role of the gasket and make the entire component stronger, after tightening the bolts, we can return half a circle to maintain the elasticity of the gasket, which is more conducive to the robustness of the entire component. However, it is necessary to ensure that the bolt is not deformed because of too tight.

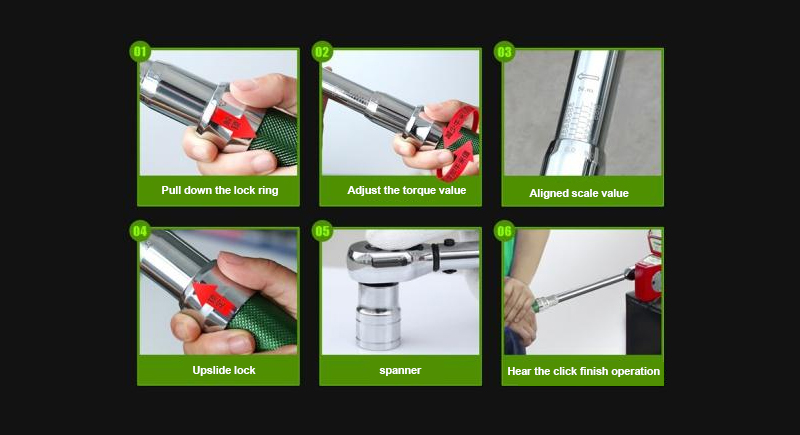

So how can we make sure the bolts don't tighten too tightly? In the manufacture of precision instruments, we need to use torque wrenches that can measure force, and in daily life, this is a little unnecessary. In daily life, screw bolts mainly rely on experience and feel, in addition, do not be around obsessive-compulsive disorder, do not always screw, always screw. Whether there is a gasket or not, the tighter the bolt, the better. For bolts without gaskets, the operation of pulling back half a turn after tightening is wrong.

Finally, let's look at what is a torque wrench? Torque wrench, also known as torque wrench, is a wrench that can adjust the size of the torque. Control the applied torque when the fastener to ensure that the thread is tight and not because the torque is too large and the thread is damaged, resulting in slippage or even fracture. Torque is the force used to turn a screw.