VIDEO & CENTER

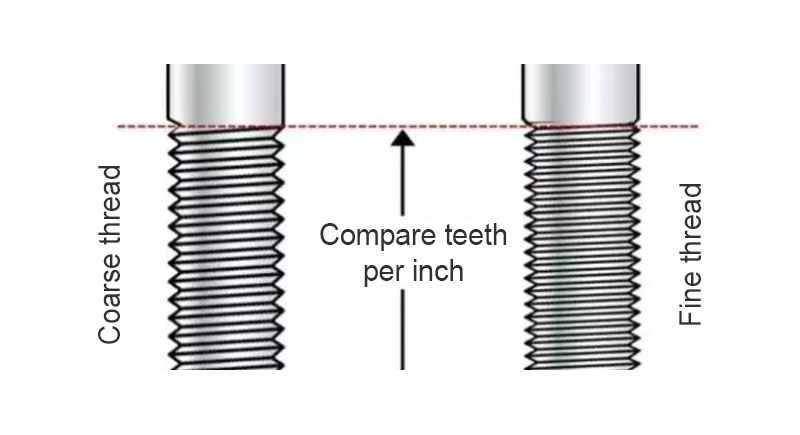

The so-called coarse thread can be defined as the standard thread; The fine thread is relative to the coarse teeth, under the same nominal diameter, the number of teeth contained per inch is different, that is, the pitch is different, the coarse tooth pitch is large, and the fine tooth pitch is small. In other words, for the 1/2-13 and 1/2-20 specifications, the former is a coarse tooth and the latter is a fine tooth. It is therefore expressed as 1/2-13UNC and 1/2-20UNF.

Since there are two different thread specifications for the same nominal diameter, how to choose coarse and fine threads?

Coarse thread

The so-called coarse teeth actually refer to the standard thread, in the absence of special instructions, we generally buy stainless steel screws and other fasteners are coarse teeth.

Coarse thread is characterized by high strength, good interchangeability, and there are standards to compare, generally speaking, coarse thread should be the best choice;

Compared with the fine thread, due to the large pitch, the thread rise Angle is also large, the self-locking property is poor, in the vibration environment need to install anti-loose washer, self-locking device; The advantage is that it is convenient to disassemble and assemble, and the supporting standard parts are complete and easy to exchange;

It is not necessary to mark the pitch when marking the coarse thread, such as M8, M12-6H, M16-7H, etc., mainly used for connecting threads.

Fine thread

Fine teeth and coarse teeth are the opposite, in order to supplement the coarse thread can not meet the special use requirements and provisions, fine thread also has a pitch series, fine tooth pitch is smaller, so its characteristics are more conducive to self-locking, anti-loose, and the number of teeth more, can reduce the effect of leakage, to achieve the effect of sealing. In some precision occasions, fine-toothed stainless steel screws are more convenient for precise control and adjustment.

The disadvantage is that the tensile value and strength are low, and the thread is easy to damage, it is not recommended to disassemble and assemble many times, and the matching nuts and other fasteners may be equally accurate, and the size is slightly wrong, which is easy to make the screws and nuts damaged at the same time.

Fine thread is mainly used in hydraulic system metric pipe fittings, mechanical transmission parts, thin wall parts with insufficient strength, internal parts limited by space and shaft with high self-locking requirements. When marking fine thread, the pitch must be marked to show the difference with coarse thread.

How to choose coarse and fine thread

Coarse thread and fine thread screws are used for fastening.

In practical applications, coarse thread is usually used, and fine thread is less used.

Fine thread is generally used in two situations:

First, it is used in places that require self-locking, such as bolts and screws on automotive transmissions, which are multi-toothed to prevent loosening due to vibration.

The second is used in thin wall, because the "tooth height" of fine thread is shorter than that of ordinary thread, due to the limitation of radial size, fine thread is used in thin wall (sleeve) occasions. There are also fine thread leads small suitable for fine tuning section.

Generally speaking, coarse thread fastening strength is higher than fine thread, so it is widely used. However, it also has a disadvantage, that is, the self-locking is worse than the fine thread, so the spring washer or other self-locking device must be installed in the place of severe vibration.

Fine thread is generally not used for large force work, it is mainly used for positioning, adjustment, fixing and so on. It is characterized by the outer diameter size of the nut can be much smaller than the standard thread, especially suitable for thin-walled cylindrical parts, such as fine threads widely used in various optical instruments. The disadvantage of fine thread is that the thread is easy to be damaged, affecting the installation and disassembly, and a slight dimensional error may lead to random buckle during installation, causing the screw and nut to be damaged at the same time.

Simply determine whether the thread is coarse or fine, first roughly determine the use of the thread, and then measure the length of n pitch with the caliper, divided by n calculation, and then check the thread table.