VIDEO & CENTER

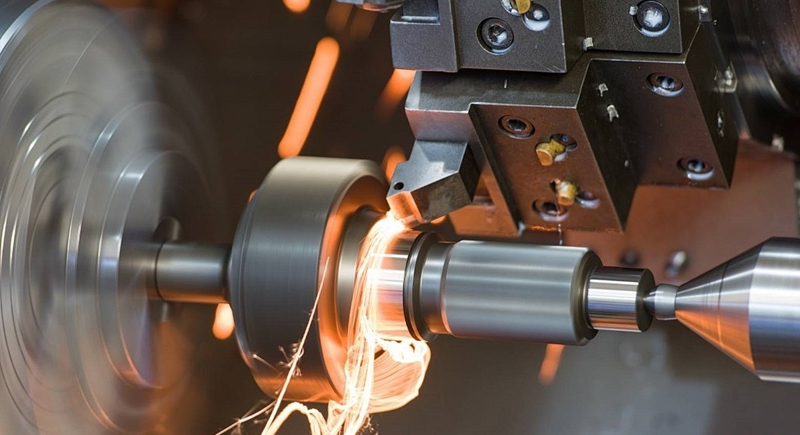

Rotating the workpiece and making the cutter head perform linear or curved motion for cutting processing. A lathe is used for machining the inner and outer cylindrical surfaces, end faces, conical surfaces, formed surfaces, and threads of parts.

When cutting internal or external cylindrical surfaces, the tool moves in a direction parallel to the rotating axis of the workpiece. When cutting end faces or cutting the workpiece, the tool moves horizontally along the axis perpendicular to the rotating axis of the workpiece. When the tool's movement trajectory forms an angle with the rotating axis of the workpiece, a conical surface can be machined. To machine the formed surface of a rotating body, either the forming tool method or the tool tip trajectory method can be used. During cutting, the workpiece is rotated by the machine tool spindle as the main motion; the lathe tool held in the tool holder performs the feed motion. The cutting speed v refers to the linear speed at the contact point between the rotating workpiece processing surface and the tool (meters/minute); the cutting depth refers to the vertical distance between the processing surface of each cutting and the processed surface (millimeters), but in cutting and forming lathe operations, it is the vertical contact length of the workpiece (millimeters). Feed refers to the displacement of the tool along the feed direction per revolution of the workpiece (millimeters/revolution), or it can be expressed as the feed per minute of the cutting tool (millimeters). When using high-speed steel lathes to machine ordinary steel, the cutting speed is usually between 25 and 60 meters/second, while for carbide lathes, it can reach 80 to 200 meters/second; when using coated carbide lathes, the maximum speed can reach more than 300 meters per minute.

Turning is typically divided into rough turning and finish turning (including semi-finish turning). In rough turning, to increase the efficiency of the turning process without reducing the cutting speed, a larger cutting depth and feed rate are selected. However, the processing accuracy can only reach IT11, and the surface roughness is between Rα20 and 10 micrometers. For semi-finish turning and finish turning, high-speed feed rates and cutting depths are used as much as possible. The processing accuracy can reach IT11 to 10 micrometers. Using a high-precision turning machine with a precision diamond turning tool to perform high-speed finishing on colored parts can achieve a processing accuracy of IT7 to 5, and a surface roughness of Rα0.04 to 0.01 micrometers, which is called "mirror turning". If a concave-convex pattern of 0.1 to 0.2 micrometers is ground on the cutting edge of the diamond turning tool, the surface of the turned part will form a very fine and neatly arranged series of ridges and valleys, which, under the effect of light diffraction, will present a lustrous appearance like brocade, and can be used as a decorative surface. Such turning is called "rainbow surface turning".

During the turning process, when the workpiece rotates, the tool also rotates at a corresponding speed ratio (the tool's rotational speed is usually several times that of the workpiece) along with the workpiece rotation. This can change the relative motion trajectory between the tool and the workpiece, allowing for the production of workpieces with polygonal cross-sections (such as triangles, squares, rhombuses, hexagons, etc.). When the tool moves longitudinally, an additional periodic radial reciprocating motion is added to the tool holder. For each rotation of the workpiece, this can produce cams or other non-circular cross-sectional curved surfaces. In the cutter-type turning machine of this utility model, the rear cutting surface of the cutter teeth can be used to process certain multi-tooth tools (such as forming milling cutters, gear broaches) in accordance with a similar working principle, and is called "cutter back".

It is easy to ensure the positional accuracy of each processing surface of the workpiece.

For example, it is easy to ensure the requirement of coaxiality.

The workpiece is installed using a chuck, and the rotational axis serves as the rotational axis of the lathe.

Install the workpiece at the front and rear ends, and the rotation axis is connected by the two centers.

- It is easy to ensure the perpendicularity of the end face to the axis by using the lateral slide plate for guidance, thus making the rotational axis of the workpiece perpendicular.

- The cutting process is relatively smooth, avoiding inertial forces and impact forces. Larger cutting volumes can be used, and high-speed cutting is possible, which is conducive to the improvement of productivity.

- Suitable for the fine processing of non-ferrous metal parts.

When the Ra value of the non-metallic part surface is not very strict, grinding processing is not recommended. Instead, turning and milling should be used. For high-quality processing, using a diamond turning tool for fine processing can achieve better results.

- The tools are simple.

The manufacturing, grinding and installation of the cutting tools are all quite convenient.