VIDEO & CENTER

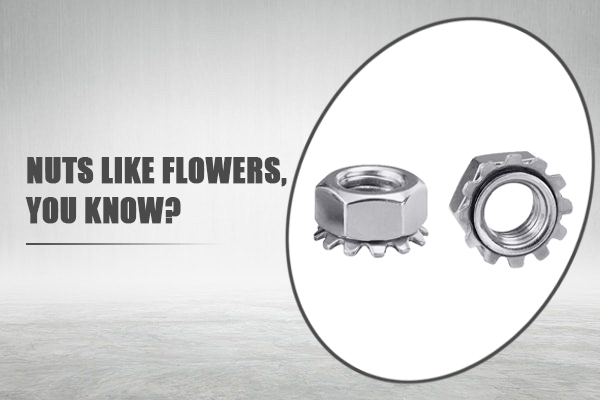

Type nut, also known as K cap or flower tooth nut, is a special structure of the nut, its main function is to lock and prevent loose. The K-nut is characterized by a removable tooth plate pressed into one end of the hexagon nut by a stamping process.

01

Structural characteristics

The main feature of the toothed K cap is that a movable tooth plate is pressed into one end of the hexagon nut by a stamping process. This design makes the nut in the locking process, can use the elastic tooth and anti-slip teeth to achieve the purpose of locking and anti-loosening.

02

Function and application

Locking and anti-loosening: The toothed K cap can provide a better locking effect because of its unique tooth structure to prevent the nut from loosening under vibration or impact conditions.

Wide application: Because of its convenient use and remarkable effect, toothed K caps are widely used in motor, mechanical assembly and other industries to ensure the stable operation of equipment.

03

Material and specification

Material: Common toothed K hat materials include stainless steel (such as 304 stainless steel) and carbon steel, etc., to meet the needs of different environments.

Specifications: Toothed K caps have a variety of specifications, usually including M3, M4, M5, M6, M8, M10 and other sizes, as well as different standards such as US and metric systems, to meet the needs of different equipment and applications.

04

Main process steps

K-nuts can be made of different materials such as carbon steel, stainless steel, aluminum alloy, brass, titanium alloy and nylon.

2, stamping:

A removable tooth plate is pressed into one end of the hexagon nut by pressing process. This tooth piece plays a key role in the locking process, using its elastic and non-slip teeth to achieve locking and anti-loosening effects.

3, surface treatment:

The surface treatment of K-nuts can include zinc plating, nickel plating, tin plating, passivation and sandblasting.